Recently DCAT announces the release of the publication of The Sustainability Leaders,an eBook presented by DCAT organization. PharmaBlock's sustainability practices and experiences have been documented in this book. PharmaBlock has been investing in multiple fronts to improve the business sustainability of the company and the industry. Let's take a look at the practices and experiences that PharmaBlock shared in the book. For more information, please read the eBook presented by DCAT:

PharmaBlock's Sustainability Journey: Innovating for a Better Future

As the demand for life-saving medicines and treatments continues to grow, so does the responsibility of the pharmaceutical industry to operate sustainably. As a fully integrated CRDMO in the pharmaceutical supply chain, PharmaBlock recognizes this responsibility and is committed to making a positive impact. The company places green chemistry and low-carbon technologies at the forefront of its sustainability efforts, along with technology-driven & lean management, and strategic backward integration strategy.

Source Design for Green Chemistry

Source design is essential for achieving environmental protection and sustainability. Designing manufacturing routes with sustainability in mind reduces the consumption of energy-intensive raw materials and waste. It involves identifying potential environmental impacts at the early stages of the development process and substituting them. At PharmaBlock, a critical area of focus is PMI (process mass intensity) control. Achieving PMI reduction on one reaction step is a key performance indicator at PharmaBlock.

To achieve this goal, the process development and manufacturing teams have implemented multiple measures, including designing optimal routes, developing low-carbon technologies for chemical reactions & post-process, and improving solvent recovery, etc.

Case: Optimal Route Scouting

Optimal route scouting is one of PharmaBlock's flagship capabilities, and it has produced numerous impressive results, including reducing waste & total number of reaction steps and improving yield. In one particular case, the team developed an optimal heavy metal-free route using SNAr reaction that avoided using Pd catalysts, simplified post-treatment, doubled the separation yield, reduced cost by 70%, and decreased the PMI from 348 to 66. Such innovative efforts helped improve production efficiency and reduce waste generation.

Case: Low-carbon Technologies

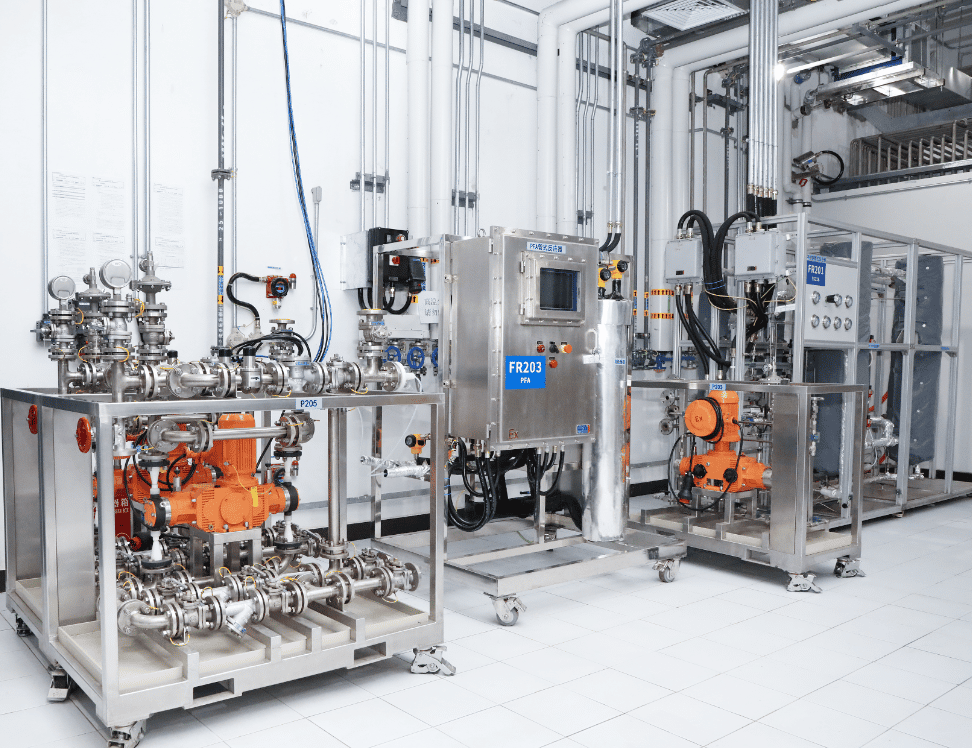

Continuous processing and flow chemistry, with its special application in micropacked bed hydrogenation and immobilized enzymes, and other technologies like biocatalysis, play a strategic role in PharmaBlock's sustainability efforts. The company applies these technologies from process design to manufacturing, improving production efficiency and reducing carbon emissions.

PharmaBlock's achievements in developing low-carbon technologies are recognized by the receipt of the 2023 ACS CMO Excellence in Green Chemistry Award. The award-winning project utilizes continuous flow processes to produce 3-oxocyclobutane-1-carboxylic acid, a building block used in the API synthesis of multiple marketed drugs. Two metric tons of the product were successfully produced in ten days. Compared to the conventional batch process, PharmaBlock's novel continuous process featuring decarboxylation, decolorization, extraction, and separation, helps achieve 20-fold energy reduction, workspace, and workforce efficiencies with far lower PMI.

Similar new technologies have been successfully implemented in over 1,500 projects at PharmaBlock. For example, PharmaBlock employs a continuous flow process in hydrogenation, using micro-packed bed reactors. Rather than using at a lab scale in the industry, PharmaBlock has taken a step further by designing and assembling manufacturing-scale equipment capable of achieving yearly outputs of hundreds of metric tons. Another remarkable application of flow technologies is eliminating the traditional batch process for nitration, which is present in about one third of pharmaceutical production. By improving thermal control, enhancing safety measures, and reducing waste, PharmaBlock has successfully transformed this corrosive process into a more efficient and eco-friendlier alternative.

Picture: Continuous Manufacturing Workshop at PharmaBlock Zhejiang

Case: Solvent Recovery

To make the process of recovering solvents used in column chromatography easier and to avoid hazardous waste, the team at PharmaBlock limited the use of specific solvents, especially the environmentally harmful chloroform. PharmaBlock took advantage of its supergravity distillation tower to recover and recycle, achieving an 85% recovery rate. These efforts resulted in 60 MT of solvents recovered yearly and a cost reduction of $200,000 each year at PharmaBlock Headquarters and the main R&D center in Nanjing.

Tech-Driven and Lean Management for Energy Efficiency and Waste Reduction

PharmaBlock integrates sustainability into daily operations, optimizing process control and end treatment with tech-driven and lean management & principles to improve efficiency.

Case: Energy Efficiency

PharmaBlock's energy control system monitors and optimizes energy consumption across its operations, using real-time data to identify areas where energy consumption can be reduced.

For example, employing preheating and thermal recycling technology for air conditioning units, such as heat exchangers to warm the dehumidified cool air, has resulted in significant energy savings. With it, a manufacturing workshop can save 150 MT of steam per year and reduce electricity consumption by 30,000 kilowatt-hours per year. These savings reduce GHG emissions and result in significant cost savings.

Case: Waste Reduction

Pharmaceutical and CDMO companies must deal with a large variety of complexities involving various chemicals. As a technology-driven player in the pharmaceutical industry, PharmaBlock has been exploring best practices.

These practices include optimizing waste gas treatment. Waste gas undergoes pre-treatment through secondary condensation, absorption, and RTO incineration to meet emission standards. However, non-condensable gases like nitrogen reduce condensation efficiency and increase exhaust concentration. Inert operations like centrifugation, filtration, and pipe blowing are standardized to minimize nitrogen consumption, resulting in a 50% reduction in workshop exhaust gas volume. With this, a 300% improvement in condensation efficiency and a 50% reduction in natural gas consumption for RTO operation is achieved.

Backward Integration to Strengthen Supply Chain Resilience

One of PharmaBlock's unique advantages in supply chain management is its experience in scaling up over 5,000 building blocks. These building blocks are used as raw materials in many drug substance and intermediate projects. This backward integration enables PharmaBlock to better back up the key raw materials sourcing, strengthens the supply chain resilience, and ensures the quality of its products. Combining green chemistry and low-carbon technologies, PharmaBlock even extends sustainability to upstream pharmaceutical production processes.

In addition, PharmaBlock is improving supplier management, including developing multiple backup sources for key materials and implementing supplier development programs. As a CRDMO company, PharmaBlock has many tier 2 and lower suppliers to monitor, and PharmaBlock believes it is essential to help lower-tier suppliers enhance sustainability awareness and operations.

Expanding the global footprint is another initiative that PharmaBlock has been working on to strengthen supply chain resilience. While having R&D and production facilities in the United States and China, PharmaBlock's continuous business planning and execution assures minimized risk exposure at all the research and manufacturing facilities.

PharmaBlock's commitment to sustainability is reflected in its various practices, such as prioritizing environmental protection, enacting responsible supply chain management, and improving drug R&D efficiency and quality. Implementing sustainable practices can come with high costs. PharmaBlock has seen the potential for significant cost savings in the long run. The journey to sustainability is a never-ending pursuit of excellence. We are committed to this mission and motivated by knowing that every small step towards these goals has great impacts and purpose.